3D hybrid placement functions

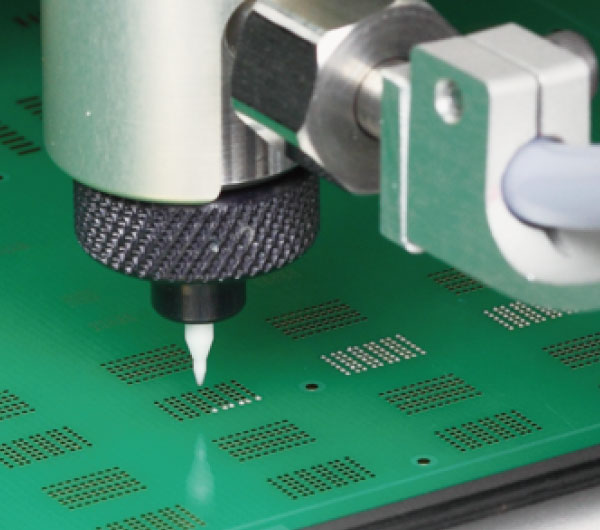

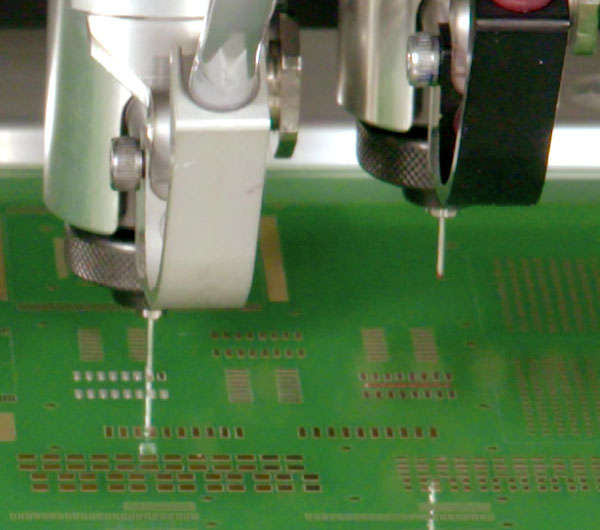

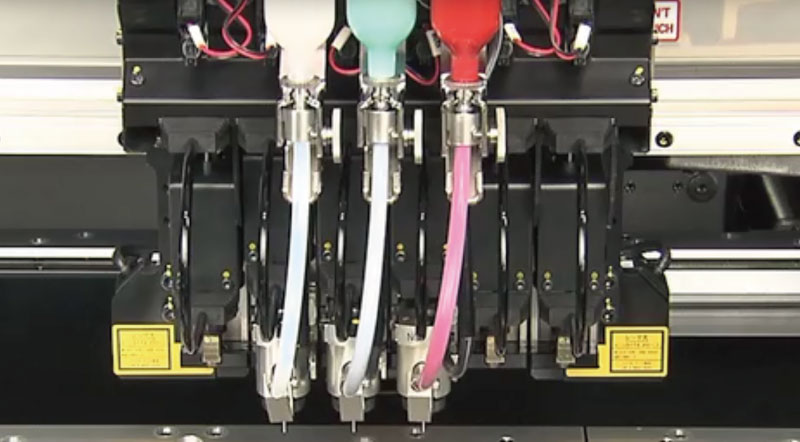

Dispense heads that can be exchanged with mount heads are newly developed. It becomes possible to make 3D placement where solder paste dispensing and component mounting can be alternately performed. Hybrid placement is now realized. The removable Dot Station can be fitted to the feeder bank.

Enhancement to 3D MID

3D MID mounting (*Custom-order specification)

Newly developed models for which dispense and placement not only on standard PCB but also on concave-convex, tilting and curved surface are also to be realized. To ensure the machine for 3D MID applications such as automotive, medical and telecommunications in future, machine structures required have already been arranged accordingly.

Large board handling capability

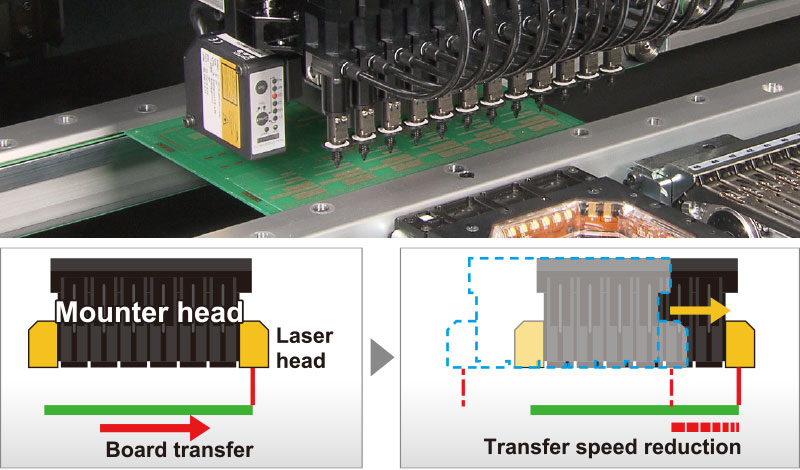

Multi-Conveyor system

Utilizing a laser sensor to measure the board length, providing optimum board position for efficient component placement, regardless of size or shape, for various production styles.

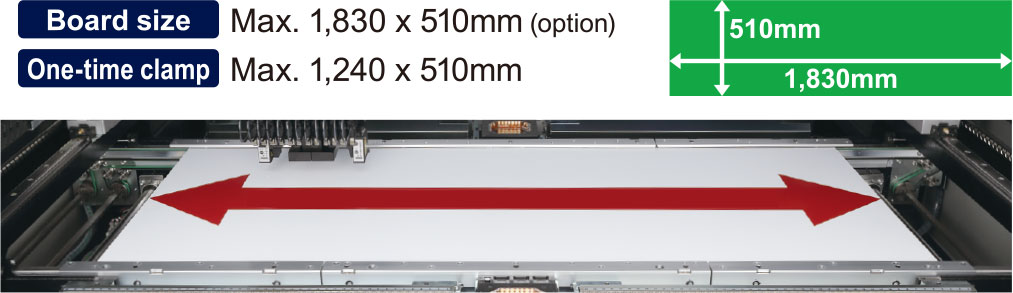

Long board handling capability

| With buffer unused | With input or output buffer used | With input and output buffers used | |

|---|---|---|---|

| S10 board size |

Max. L955 x W510mm(standard) |

Max. L420 x W510mm |

Max. L330 x W510mm |

| S20 board size |

Max. L1,455 x W510mm(standard) |

Max. L540 x W510mm |

Wide ranging component handling capability and high feeder capacity

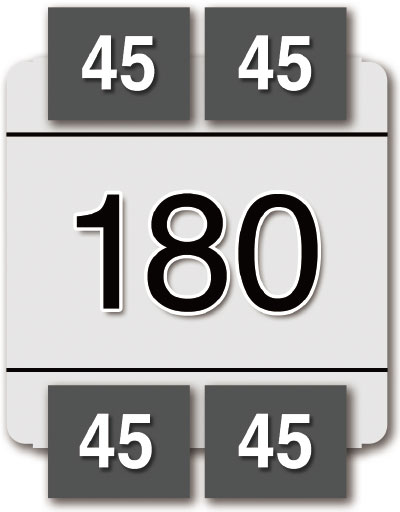

Max. feeder capacity 180 lanes

S20 : S20 Max. 180 types (8mm tape conversion), 45 lanes x 4

S10 : S10 Max. 90 types (8mm tape conversion), 45 lanes x 2

ANC station

Nozzle ID automatically recognized. The standard ANC station can accommodate 24 nozzles. As a variation, an optional ANC station that can accommodate 40 nozzles is also available.

Wide ranging component handling capability

0201mm ultra-tiny chip (option) up to max. 120 x 90mm components can be handled by a single standard camera. Max. component height is 30mm (component height + board thickness), the greatest class on the market.

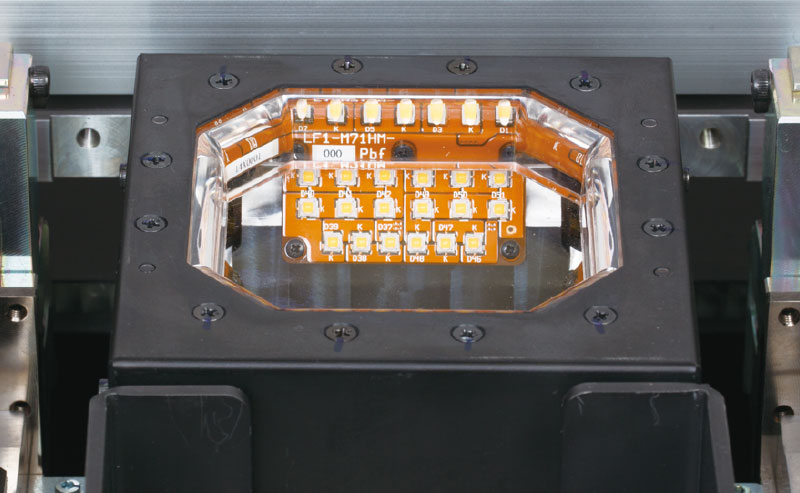

Color fiducial camera

Great upgrades in fiducial recognition performance! These include colorizing for fiducial recognition cameras and a newly developed lighting unit. Robust coating inspections are now a reality. (To be customized)

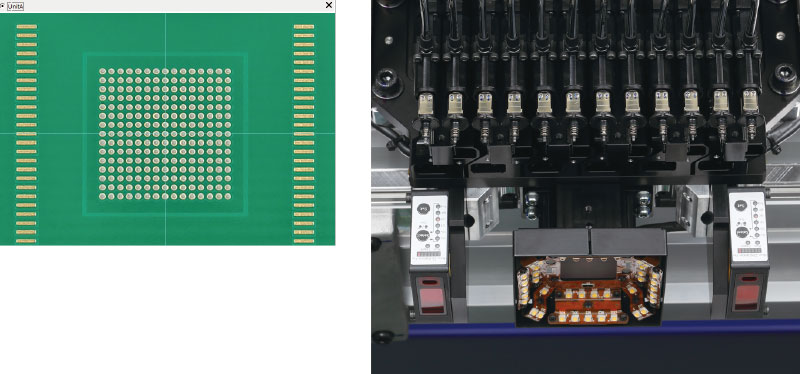

New head unit for higher speed placement

12-axis 2-theta head unit

Newly developed for higher speed placement is best suited for a long board production such as LED lighting.

6-axis 2-theta head unit

The 6-axis 2-theta head ideal for hybrid mounting tasks achieves the ultimate 1-head solution for mounters covering the process from dispensing to mounting to inspection.

Ultimate flexibility and fast & easy setup

CFB/CTF full compatibility

The newly developed CFB-45E as well as the existing CFB’s and CTF can be all used together on the M10 and M20 as well as on the S10 and S20.

Applicable CFB and CTF

- F3 45-lane Feeder Bank Changer “CFB-45E”

- F3 36-lane Feeder Bank Changer “CFB-36E”

- Changeable Tray Feeder “CTF-36C”

※Fitted to S20 on the pictures below.

Options

- 6 axis 2-theta head

- Air pulse type dispense head

- Screw pump type dispense head

- ANC40

- 0201mm chip handling capability

- Dispensed dot check function(To be customized)

- 3D-MID

- Rear fixed multi-scan camera

- F3 / F1 / F2 Rear side fixed feeder bank

- F3 45-lane fixed feeder bank

- Safety cover, front/rear

- Clamp unit for CFB/CTF

- CFB-36E / CFB-45E F3 Electric Feeder Bank Changer

- CTF-36C Cassette type Changeable Tray Feeder

- FTF-36C Cassette type Fixed Tray Feeder

- RTS-1 Removable Tray Station

- Parts feeders

- Rear side operation system

- Rear side switches

- UPS4

- Conveyor extension, entrance/exit

- Component setup verifier

- Feeder relocatability

- Waste tape box

- Internal lighting

- Lead coplanarity sensor

- Offline software

- iQvision

Reviews

There are no reviews yet.