Specification

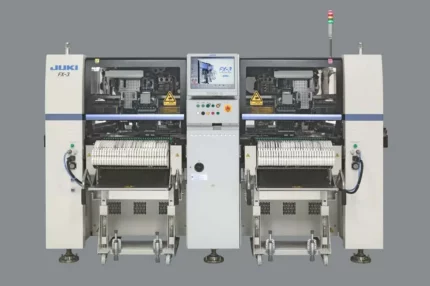

| High-Speed Compact Modular Mounter RX-6R | |||

|---|---|---|---|

| Board size | Single lane conveyor | 50×50 ~ 610×590 / 905×590mm(2times clamping) | |

| Dual lane conveyor | – | ||

| Component height | 6 / 12 / 20mm | ||

| Component size | Laser recognition | 0402 ~ 50mm×50mm | |

| Vision recognition*2 | Standard camera | 3mm×3mm ~ 33.5mm×33.5mm | |

| High-resolution camera | 1005 ~ 24mm×24mm | ||

| Placement speed | Chip | Optimum*3 | 52,000CPH |

| IPC9850 | 29,000CPH | ||

| IC*4 | 14,000CPH | ||

| Placement accuracy | Laser recognition | ±0.04mm(Cpk≧1)*5 | |

| Vision recognition*2 | ±0.04mm | ||

| Component loading quantity | Max.160 in case of 8mm tape (on a Electric double tape feeder) |

||

| High-Speed Compact Modular Mounter RX-6B (6×6 nozzle head) | |||

|---|---|---|---|

| Board size | Single lane conveyor | 50×50 ~ 610×590 / 905×590mm (2 times clamping) | |

| Dual lane conveyor | 50×50 ~ 360×250mm*1 | ||

| Component height | 6 / 12 / 20 / 25 / 33mm | ||

| Component size | Laser recognition | 0402 ~ 50mm×50mm | |

| Vision recognition*2 | Standard camera | 3mm×3mm ~ 33.5mm×33.5mm | |

| High-resolution camera | 1005 ~ 20mm×20mm | ||

| Placement speed | Chip | Optimum*3 | 42,000CPH |

| IPC9850 | 26,000CPH | ||

| IC*4 | 14,000CPH | ||

| Placement accuracy | Laser recognition | ±0.04mm(Cpk≧1) | |

| Vision recognition*2 | ±0.04mm | ||

| Component loading quantity | Max.160 in case of 8mm tape(on a Electric double tape feeder) | ||

| High-Speed Compact Modular Mounter RX-6B (6×3 nozzle head) | |||

|---|---|---|---|

| Board size | Single lane conveyor | 50×50 ~ 610×590 / 905×590mm (2times clamping) | |

| Dual lane conveyor | 50×50 ~ 360×250mm*1 | ||

| Component height | 6 / 12 / 20 / 25 / 33mm | ||

| Component size | Laser recognition | 0402 ~ 33.5mm×33.5mm | |

| Vision recognition*2 | Standard camera | 3mm×3mm ~ 100mm×100mm / 50×180mm | |

| High-resolution camera | 1005 ~ 48mm×48mm / 24mm×72mm | ||

| Placement speed | Chip | Option*3 | 34,000CPH |

| IPC9850 | 23,000CPH | ||

| IC*4 | 11,000CPH | ||

| Placement accuracy | Laser recognition | ±0.04mm(Cpk≧1) | |

| Vision recognition*2 | ±0.03mm | ||

| Placement loading quantity | Max.160 in case of 8mm tape (on a Electric double tape feeder) |

||

*1 Single lane conveyor specification mode max 360×450mm

*2 Option

*3 When using the single lane conveyor specification

*4 Placement speed of IC components is estimated value when placing 36 pieces QFP component (dimension 10mm square or smaller) on M size PWB overall,picking from both front and rear side with all nozzles simultaneously.

*5 Under the JUKI condition

Reviews

There are no reviews yet.