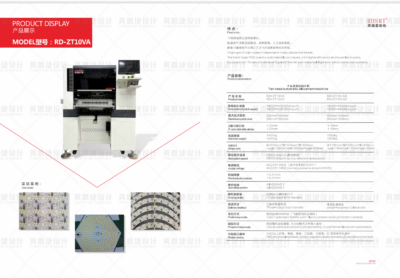

Rongde RD-ZT10VA high-speed placement machine

Enquiry

Categories: MADE IN CHINA MACHINE, SMT placement machine

Description

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Be the first to review “Rongde RD-ZT10VA high-speed placement machine” Cancel reply

Related products

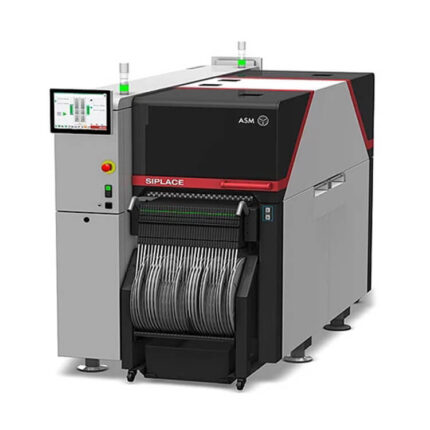

SMT ASM Siemens Mounter Placement machine SIPLACE SX4

Panasonic NPM-W2 Multifunctional Mounter placement machine

Product Features of Panasonic NPM-W2 Multi-Function Mounter

1. Install & inspect a complete system to achieve efficient and high-quality production

To match the actual installation requirements, you can choose high-yield or high-precision mode

2. Can correspond to larger substrates and large components

Correspondingly, on a large substrate of 750×550 mm, the component range is also expanded to L150×W25×T30mm

3. Double-track installation (select specifications) to achieve high productivity per unit area

According to the production substrate, you can choose independent mounting, alternate mounting, mixed mounting and other mounting methods

SMT placement machine Samsung placement machine SM471Plus

High-performance chip shooter with a new fly camera

· World's highest speed of 78,000CPH among chip shooters of the same class

· With two gantry dual-lane construction, supports various production modes

-

Specifications

- Alignment

- Fly Camera

- Spindle & Speed

- 2 Gantry * 10 Spindle / 78,000 CPH

- Accuracy

- ±40μm@±3σ (Chip) / ±50μm@±3σ (QFP)

- Component Range

- 0402 ~ □14mm

- Dimension

- L 1,650 x D 1,690 x H 2,045

SMT placement machine Siemens ASM SIPLACE HS50 high-speed placement machine

SMT placement machine ASM Siemens placement machine TX2i/TX2/TX1

Introduction to ASM Siemens Mounter TX2i: ASM Siemens Mounter TX2i: Provide high performance and high precision in a very small footprint. The ASM Siemens Mounter TX2i mounter module sets a new benchmark for mass production. No other placement solution can achieve 25 µm @ 3 sigma accuracy at speeds up to 96,000 cph in such a small footprint (only 1m x 2.3m).

Samsuang Hanwha DECAN F2

Specifications

- Alignment

- Fly Camera, Fix Camera

- Spindle & Speed

- 2 Gantry * 10 Spindles / 80,000 CPH

- Accuracy

- ±40µm Cpk≥1.0 (0402 (01005 inch) chip) /±30µm Cpk≥1.0 (IC, Stage Vision)

- Component Range

- Fly: 0402 ~ □16 mm / Fix: ~□42 mm (Standard) / ~□55 mm (MFOV) / ~ L75 mm Connector (MFOV)

- Dimension

- L 1,430 x D 1,740 x H 1,995

Panasonic CM202 placement machine Mounter

Main parameters of CM202 placement machine:

2004 equipment

PCB size: 460mm×360mm

Component range that can be attached: 0201 to 24mmQFPS

Material station: 104

Theoretical placement speed: 0.088s/chip 40909 pieces/hour

Mounting accuracy: ±0.05mm

Dimensions and Weight: 2,350(L) X 1,950(D) X 1,430(H)mm&2,800kg

Power supply and air source: 3P/200V±10V/3KVa

Yamaha 3D Hybrid Modular S10/S20 Mounter placement machine

Specifications

| S10 | S20 | |

|---|---|---|

| Board size(with buffer unused) | Min. L50 x W30mm to Max. L1,330 x W510mm (Standard L955) | Min. L50 x W30mm to Max. L1,830 x W510mm (Standard L1,455) |

| Board size(with input or output buffer used) | Min. L50 x W30mm to Max. L420 x W510mm | - |

| Board size(with input and output buffers used) | Min. L50 x W30mm to Max. L330 x W510mm | Min. L50 x W30mm to Max. L540 x W510mm |

| Board thickness | 0.4 - 4.8mm | 0.4 - 4.8mm |

| Board flow direction | Left to right (Std) | Left to right (Std) |

| Board transfer speed | Max 900mm/sec | Max 900mm/sec |

| Placement speed (12 heads + 2 theta) Opt. Cond. | 0.08sec/CHIP (45,000CPH) | 0.08sec/CHIP (45,000CPH) |

| Placement accuracy A (μ+3σ) | CHIP +/-0.040mm | CHIP +/-0.040mm |

| Placement accuracy B (μ+3σ) | IC +/-0.025mm | IC +/-0.025mm |

| Placement angle | +/-180 degrees | +/-180 degrees |

| Z axis control / Theta axis control | AC servo motor | AC servo motor |

| Component height | Max 30mm*1 (Pre-placed components: max 25mm) | Max 30mm*1 (Pre-placed components: max 25mm) |

| Applicable components | 0201mm – 120x90mm, BGA, CSP, connector, etc. (Standard 01005 -) | 0201mm – 120x90mm, BGA, CSP, connector, etc. (Standard 01005 -) |

| Component package | 8 - 56mm tape (F1/F2 Feeders), 8 - 88mm tape (F3 Electric Feeders), stick, tray | 8 - 56mm tape (F1/F2 Feeders), 8 - 88mm tape (F3 Electric Feeders), stick, tray |

| Drawback check | Vacuum check and vision check | Vacuum check and vision check |

| Screen language | English, Chinese, Korean, Japanese | English, Chinese, Korean, Japanese |

| Board positioning | Board grip unit, front reference, auto conveyor width adjustment | Board grip unit, front reference, auto conveyor width adjustment |

| Component types | Max 90 types (8mm tape), 45 lanes x 2 | Max 180 types (8mm tape), 45 lanes x 4 |

| Transfer height | 900 +/- 20mm | 900 +/- 20mm |

| Machine dimensions, weight | L1250xD1750xH1420mm, Approx. 1,200kg | L1750xD1750xH1420mm, Approx. 1,500kg |

- *1 :

- Board thickness + Component height = Max 30mm

- Specifications and appearance are subject to change without prior notice.

Reviews

There are no reviews yet.