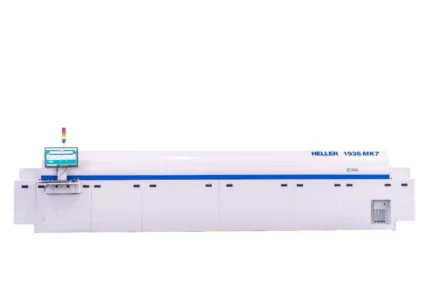

1936MK5 Reflow Oven System

- Product Name: Lead-Free Reflow Oven System

- Product Model: 1936MK5

- Product Brand: Heller

Heller 1936MK5 reflow oven provides the ultimate high volume production solutions with belt speeds up to 1.4 m/min to accommodate the fastest pick and place systems.

Key Features

- Nitrogen / Air Lead-Free Soldering Reflow Oven

- Enhanced Heater Modules & Fastest Cooling Rates

- Lowest Nitrogen & Electrical Usage

- Maintenance Free Design

- One-Step Profiling

- Reflow Oven Process Monitoring Tools

- Dual Lane Design for High Throughput Capacity

Specifications

| Machine Model | Heller 1936MK5 |

| Heating Zones | Top 10 / Bottom 10 |

| Cooling Zones | Top 3 |

| PCB Width | 50 – 610 mm |

| Max Conveyor Speed | 188 cm/min |

| Cross-Belt Temperature Tolerance | ± 2 ℃ |

| Accuracy of Temperature Controller | ± 0.1 ℃ |

| Conveyor Width Adjustment | Manual Motor Control |

| Operating System | Windows 7 |

| Overall Dimensions | W5890 x D1370 x H1600 mm |

| Typical Net Weight | Approx. 2900 kg |

Reviews

There are no reviews yet.