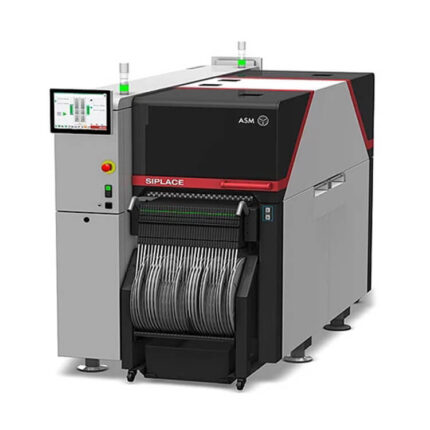

Siemens/ASM Siplace X 24mm Feeder

Description

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Be the first to review “Siemens/ASM Siplace X 24mm Feeder” Cancel reply

Related products

High-efficiency Modular Z:LEX YSM20WR Mounter placement machine

Specifications

| Model | YSM20WR |

|---|---|

| Applicable PCB | Dual lane Note 1 Same type PCBs: L810 x W356 to L50 x W50 Different type PCBs: up to L810 x W662 Note 2 Same type PCB: L810 x W280 to L50 x W500 Different type PCBs: up to L810 x W510 |

| Head / Applicable components | High-Speed Multi (HM) Head Note 3 0201mm to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) | X axis 2-beam Note 1: High-speed multi-purpose (HM: High-speed Multi) head x 2 81,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 2,110 x H1,445mm (Main unit only) |

| Weight | Approx. 2,500kg (Main unit only) |

- Note 1 : When using conveyor separation specifications of 787mm between 1 to 4 lanes

- Note 2 : When using conveyor separation specifications of 630mm between 1 to 4 lanes

- Note 3 : Please contact us for info regarding mounting 0201mm components.

- Specifications and appearance are subject to change without prior notice.

Samsuang Hanwha DECAN F2

Specifications

- Alignment

- Fly Camera, Fix Camera

- Spindle & Speed

- 2 Gantry * 10 Spindles / 80,000 CPH

- Accuracy

- ±40µm Cpk≥1.0 (0402 (01005 inch) chip) /±30µm Cpk≥1.0 (IC, Stage Vision)

- Component Range

- Fly: 0402 ~ □16 mm / Fix: ~□42 mm (Standard) / ~□55 mm (MFOV) / ~ L75 mm Connector (MFOV)

- Dimension

- L 1,430 x D 1,740 x H 1,995

Yamaha High-efficiency Modular Z:LEX YSM20R Mounter placement machine

Specifications

| Model | YSM20R |

|---|---|

| Applicable PCB | Single lane L810 x W490 to L50 x W50 Dual stage Note: For X-axis 2-beam option only 1PCB conveyance: L810 x W490 to L50 x W50 2PCB conveyance: L380 x W490 to L50 x W50 |

| Head / Applicable components | High-Speed Multi (HM) Head * 0201mm to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) | X axis 2-beam: High-speed multi-purpose (HM: High-speed Multi) head x 2 95,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 1,857 x H1,445mm (Main unit only) |

| Weight | Approx. 2,050kg (Main unit only) |

SMT placement machine ASM Siemens placement machine TX2i/TX2/TX1

Introduction to ASM Siemens Mounter TX2i: ASM Siemens Mounter TX2i: Provide high performance and high precision in a very small footprint. The ASM Siemens Mounter TX2i mounter module sets a new benchmark for mass production. No other placement solution can achieve 25 µm @ 3 sigma accuracy at speeds up to 96,000 cph in such a small footprint (only 1m x 2.3m).

SMT Samsung Mounter SM481Plus 481

Samsung Hanwha High Speed Mounter DECANS2

Specifications

- Alignment

- Fly Camera, Fix Camera

- Spindle & Speed

- 2 Gantry * 10 Spindle / 92,000 CPH

- Accuracy

- ±28 μm @ Cpk ≥ 1.0 (03015 Chip) / ±25 μm @ Cpk ≥ 1.0(IC)

- Component Range

- Fly: 03015 ~ □12 mm / Fix: ~□42 mm (Standard) / ~□55 mm (MFOV) / ~ L75 mm Connector (MFOV)

- Dimension

- L 1,430 x D 1,740 x H 1,995

Panasonic Mounter CM602-L high-speed placement machine

Control mode: microcomputer mode

External memory: Manage data at PT∗4. Each set of data requires about 1MB. (1 type is required for each 1 type 3.5 2HD floppy disk)

Program data: Points Max. 10000 points

CM602 power supply

Power supply for normal use: 3-phase AC 200 V/ 220 V ±10 V, 3-phase AC 380 V/ 400 V/ 420 V/ 480 V ±20 V Frequency: 50/60 Hz

Power supply for HUB ∗ 3: Single-phase AC 100 V ~ AC 240 V Frequency: 50/60 Hz

Rated capacity: main machine 4.0 kVA / HUB power supply ∗ 3: 140 VA

Supply air pressure: 0.49 MPa ~ 0.78 MPa (operating air pressure is 0.49 MPa ~ 0.54 MPa)

Supply air volume: 170 L/min (A.N.R.)

Dimensions: 2350 mm (W) × 2690 mm (D) × 1430 mm (H) (excluding 3-section signal tower and color touch panel)

quality:

Mass of the main engine: 3400 kg (140 kg for the standard configuration without the overall exchange trolley)

Overall exchange trolley mass: 140 kg (per 1)

Direct tray feeder mass: 195 kg (per 1 unit)

Standard composition mass: 3960 kg (1 main engine, 4 overall exchange trolleys)

Environmental conditions: Temperature: 10°C ~ 35°C Humidity: 25% RH ~ 75% RH (but water vapor does not condense)

Transport and storage conditions: Temperature: −20°C ~ 60°C Humidity: Below 75 % RH (but water vapor does not condense)

Altitude: from 0 m above sea level to below 1000 m

Noise: < 70dB (A)

Reviews

There are no reviews yet.