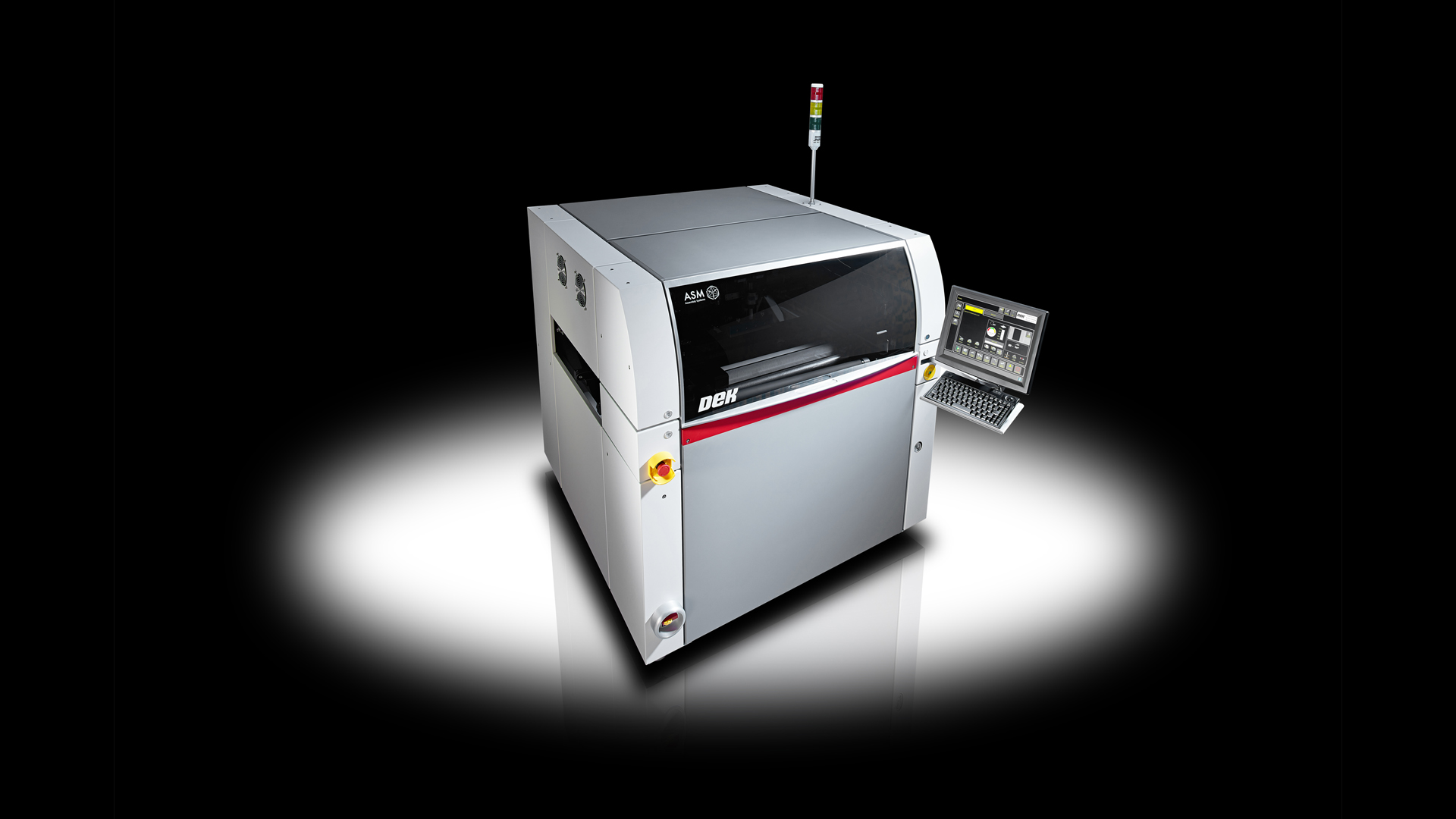

DEK Horizon 03ix Screen Printer

DEK NeoHorizon 03 iX automatic solder paste printing machine Screen Printer

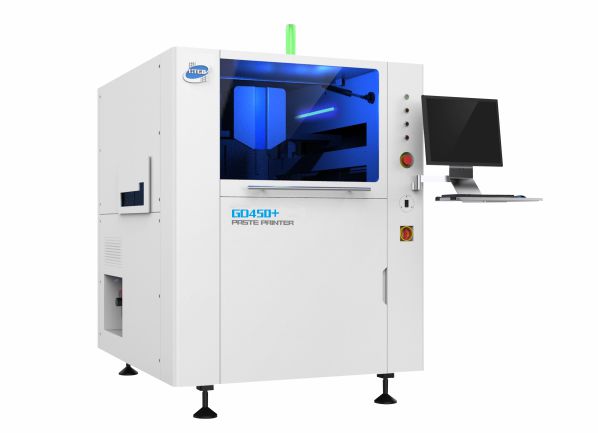

DESEN Classic 1008 automatic solder paste printing machine Screen Printer

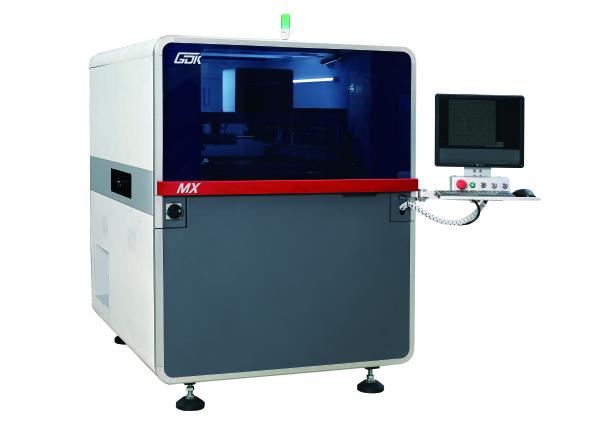

GKG-G5 automatic solder paste printing machine Screen Printer

GKG-G5 automatic solder paste printing machine features:

1. GKG special adjustable jacking platform, with reliable structure and convenient adjustment, can quickly realize the adjustment of the jacking height of PIN pins of PCB boards with different thicknesses.

2. Brand-new optical path system—uniform ring light and high-brightness coaxial light, together with the brightness function that can be adjusted steplessly, makes all types of Mark points can be well identified, suitable for tin plating, copper plating, Gold-plated, HASL, FPC and other types of PCBs of different colors. GKG's patented mathematical operation mode ensures that the machine can achieve high-precision alignment.

3. It adopts Windows XP/Win7 operation interface, which has a good man-machine dialogue function: especially in the navigation effect of program files, which is convenient for operators to quickly familiarize themselves with the operation; menu-style Chinese/English switching, operation log, fault record/fault self-diagnosis /Fault analysis prompt/light alarm and other functions make the operation simple and convenient.

4. There are three cleaning methods: dry cleaning, wet cleaning and vacuum cleaning. The three cleaning methods can be used in any combination, and when the customer does not need automatic cleaning, manual cleaning can be realized under the production interface, thereby shortening the cleaning time and improving production efficiency.

5. The highly adaptable steel screen frame clamping system can realize the printing of screen frames of various sizes, and can realize the rapid replacement of models during the production process.

6. Image rail system: detachable, programmable flexible side clamping device, for soft boards, warped PCBs, unique top flattening, through software programming, it can automatically expand and contract without affecting the tin thickness.

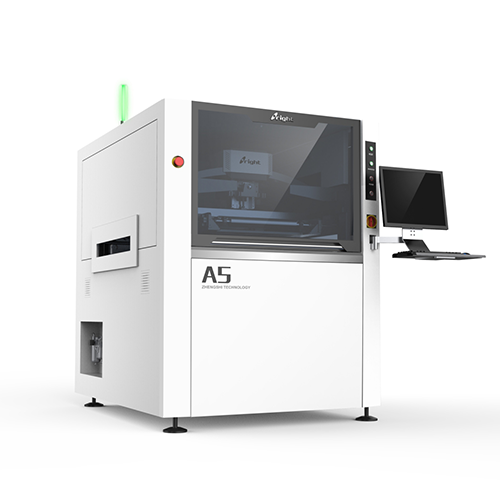

Right A5 automatic solder paste printing machine Screen Printer

● Humanized design

● Wide application range and strong versatility

● Unique sprinkler automatic cleaning system

● Efficient energy-saving wiping paper -saving structure

● Unique image processing system

● Intelligent printing production mode

● Printing range: 400*340mmm

● Use international universal UVW three axis linkage platform

● Machine dimension : 1220X1355X1500mm

● Machine option : automatic add solder paste function. automatic stencil inspection function .automatic dispensing system .squeegee pressure feedback function .automatic MSE/SPI online function .automatic constant temperature and humidity function

Right A9 automatic solder paste printing machine Screen Printer

● Humanized design

● Unique sprinkler automatic cleaning system

● Efficient energy-saving wiping paper-saving structure

● Unique image processing system

● Intelligent printing production mode

● Pringting range: 510*340mm

● Use international universal UVW three axis linkage platform

● High accuracy .high speed .high stability . production of smart wearable products/phone preferred

● Machine dimensions range : 1220X1355X1500mm

● Machine option : automatic add solder paste function. automatic stencil inspection function .automatic dispensing system .squeegee pressure feedback function .automatic MSE/SPI online function .automatic constant temperature and humidity function