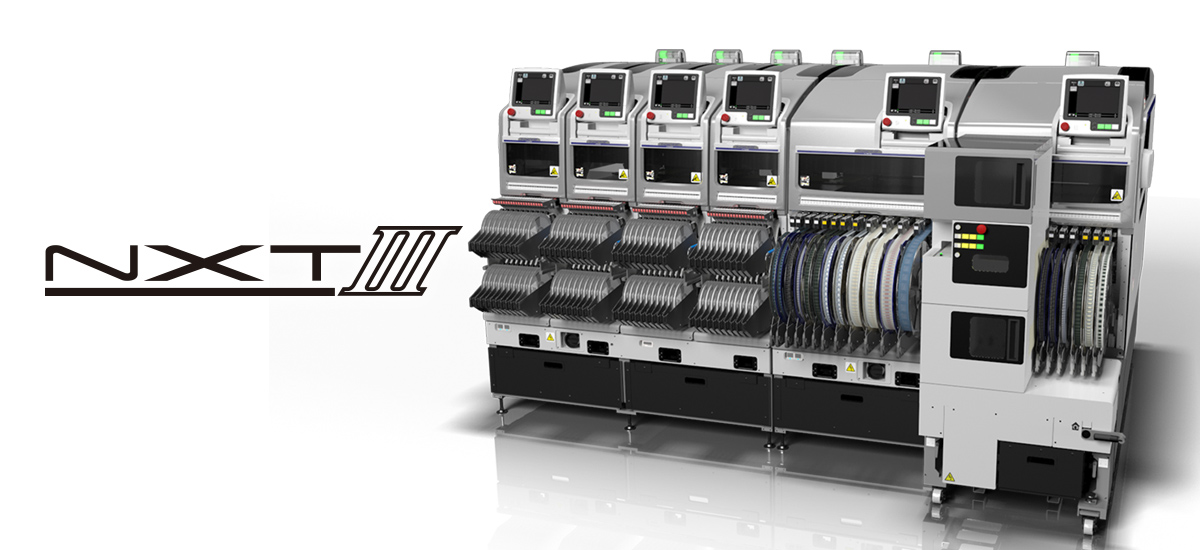

FUJI Fuji NXT third-generation placement machine parameter details:

| MACHINE | M3III | M6III | ||||||

| FEEDER NUMBERS | 20 | 45 | ||||||

| PCB SIZE (L x W) |

single handling track | 48×48~305X610mm | 48X48~610x610mm | |||||

| double handling track | single handling track | 48×48~305x510mm | 48×48~610x510mm | |||||

| double handling track | 48×48~305x280mm | 48X48~610X280mm | ||||||

| HEAD | H24S、H24A、DX※1、V12、H12HS(Q)、HO8M(Q)※1、 HO8(Q)、 | |||||||

| H04SF、H04、HO2F、H01、OF※1、GO4F(Q)、GL | ||||||||

| production capacity | H24S/H24A | standard mode | 35,000cph | |||||

| production priority mode | 42,000cph | |||||||

| H08M | standard mode | 13,000cph | ||||||

| production priority mode | 14.000cph | |||||||

| H02F | standard mode | 6,700cph | ||||||

| production priority mode | 7,400cph | |||||||

| Mounting accuracy | H24S/H24A | standard mode | ±0.025 mm Cpk1,00 | |||||

| high accuracy mode | ±0.015 mm Cpk1,00 | |||||||

| H08M | HO8M ±0.040 mm Cpk100 | |||||||

| H02F | HO2F ±0.025 mm Cpk1.00 | |||||||

1. Achieve high productivity

In addition to increasing the speed of the XY manipulator and feeder, this machine also improves the placement capability of all components from micro components to large special-shaped components by using the “Fly Vision” camera.

If combined with the newly developed “H24S working head”, the production capacity of one module will be as high as 42,000cph* (in production priority mode).

※Test results under the conditions specified by our company.

2. Can mount 0201 type components (0.25×0.125 mm)

Mounting accuracy ±15μm* (in high-precision mode)

In addition to producing the smallest 03015-size components among commonly used parts at this stage, the third-generation Fuji placement machine NXT can also mount future-oriented ultra-small 0201-size components.

Its body structure has higher rigidity than the old model, combined with exclusive servo control technology and component image recognition technology, so as to achieve the industry’s top small chip placement accuracy ±15μm*2 (3σ) Cpk≧1.00.

*1 Test results under the conditions specified by our company.

※2 Results of our company’s research.

3. Effective use of existing equipment

The main feeding equipment, material station brackets, material station carts, etc. used in the Fuji placement machine NXT II, including the working head, nozzle placement table, feeder, and tray unit, are compatible with NXT III , contribute to the effective use of equipment.

intuitive operation

The FUJI/NXT placement machine series all adopt the GUI interface with high evaluation. NXTⅢ also continues to use the non-text-based intuitive operating system, and on this basis, it uses a touch screen and changes the screen design.

To sum up, compared with the previous operating system, the new machine not only reduces the number of clicks, but also makes it easier to find the next instruction, thereby improving operability and reducing the probability of misoperation.

Reviews

There are no reviews yet.