Technical Parameters

Model VS-800/VS-800-N VS-1000/VS-1000-N NS-800/NS-800-N NS-1000/NS-1000-N

Machine parameters

Dimensions (L*W*H) 5606×1350×1440mm 6376×1350×1440mm 5606×1350×1440mm 6376×1350×1440mm

Color Computer Gray Computer Gray Computer Gray Computer Gray

Weight about 2250kg about 2450kg about 2250kg about: 2450kg

Number of heating zones Upper 8 / Lower 8 Upper 10 / Lower 10 Upper 8 / Lower 8 Upper 10 / Lower 10

Heating zone length 3121mm 3891mm 3121mm 3891mm

Number of cooling zones 2 (built-in) 2 (built-in) 2 (built-in) 2 (built-in)

Air volume requirements 10 M3 / min x 2 sets 10 M3 / min x 2 sets 10 M3 / min x 2 sets 10 M3 / min x 2 sets

control section parameters

Power requirements 3 phase, 380V 50/60HZ (3 phase 220V 50/60Hz optional)

Power requirements 64KW / 67KW 80KW / 83KW 64KW / 67KW 80KW / 83KW

Starting power 23KW / 24KW 29KW / 30KW 23KW / 24KW 29KW / 30KW

Normal operating power 12KW / 14KW 14KW / 16KW 12KW / 14KW 14KW / 16KW

The heating time is about 25 min.

Temperature control range from room temperature to 300°C

Temperature control mode PID closed-loop control + SSR drive

Temperature control accuracy ± 1°C

PCB board temperature distribution deviation ± 1.5°C

Parameter storage Can store a variety of production setting parameters and conditions (40GB)

Abnormal alarm temperature abnormality (ultra-high temperature or ultra-low temperature after constant temperature)

Board drop alarm Three-color signal lights: yellow-heating; green-constant temperature; red-abnormal

Shipping parameters

PCB Width Max. Width Of PCB 400mm

Guide rail width adjustment range / width adjustment form 50~400mm / electric

Component height 25mm on PCB board, 25mm below

Transport direction left to right (optional: right to left)

Transport rail fixing method front-end fixed (optional: rear-end fixed)

PCB transportation method chain drive (standard) / mesh belt drive (nitrogen furnace is optional

Conveyor belt height 900±20mm

Conveyor belt speed 0~2000mm/min

Reflow Thermal Engineering Management Analysis

Thermal engineering real-time monitoring system (US KIC 24/7 system) Standard configuration None

other

Nitrogen system (Nitrogen reserve structure) Oxygen analyzer; Nitrogen flow meter

Flux management Furnace air circulation and filtration, optimize the furnace environment, easy maintenance

Chiller 3HP external, sufficient cooling capacity for lead-free process requirements

Central support prevents PCB board from bending due to excessive width and component weight

Description

Shipping & Delivery

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

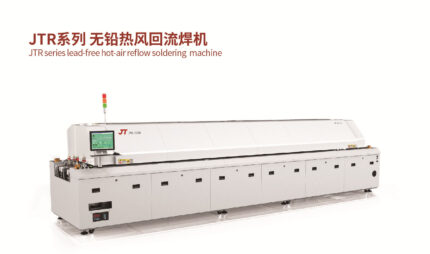

Be the first to review “JT NS-800 II Reflow Oven System” Cancel reply

Related products

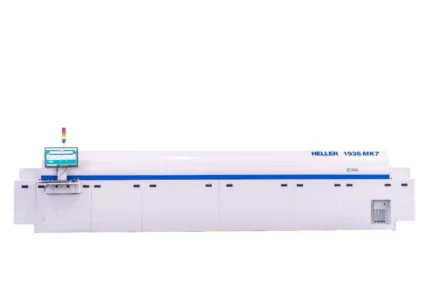

Heller1936 MK7 Reflow Oven System

The 1936 MK7 is a high volume reflow oven system with 10 heated zones and belt speeds up to 1.88m/min. The 1936 MK7 offers the lowest delta T’s, reduced nitrogen and electrical consumption and advanced flux management options. The 12” wide heater modules offer profile compatibility with competitor systems.

- Built-in Thermal Monitoring

- Nitrogen Capable to < 100 ppm

- Energy Management System

- Virtually No Maintenance

- 12” Wide Heater Modules

Reviews

There are no reviews yet.