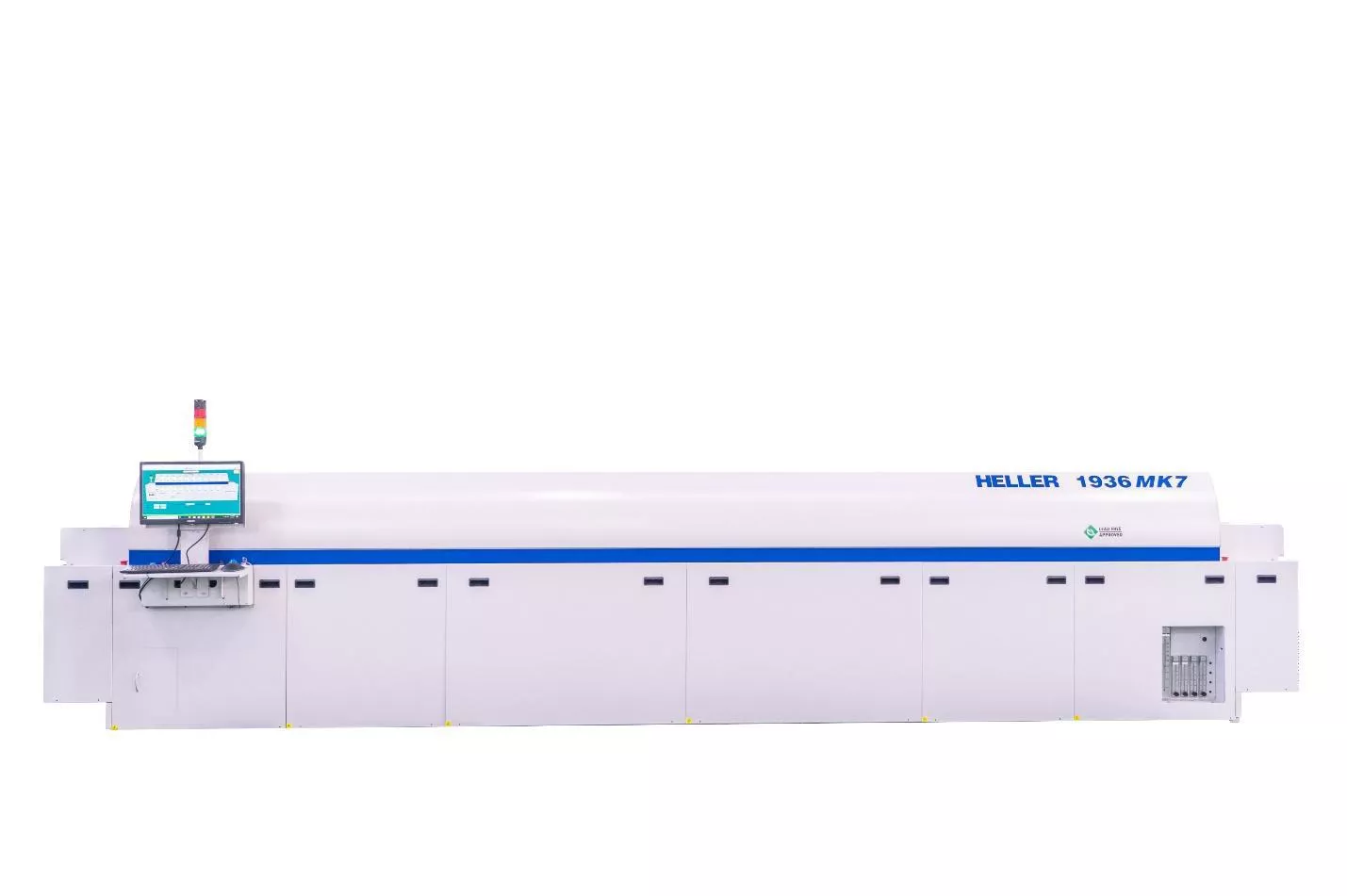

Heller1936 MK7 Reflow Oven System

The 1936 MK7 is a high volume reflow oven system with 10 heated zones and belt speeds up to 1.88m/min. The 1936 MK7 offers the lowest delta T’s, reduced nitrogen and electrical consumption and advanced flux management options. The 12” wide heater modules offer profile compatibility with competitor systems.

- Built-in Thermal Monitoring

- Nitrogen Capable to < 100 ppm

- Energy Management System

- Virtually No Maintenance

- 12” Wide Heater Modules

High temperature resistance Adjustable Aluminum alloy side plate ESD PCB Magazine Rack SMT PCB Storage Rack

High-efficiency Modular Z:LEX YSM20WR Mounter placement machine

Specifications

| Model | YSM20WR |

|---|---|

| Applicable PCB | Dual lane Note 1 Same type PCBs: L810 x W356 to L50 x W50 Different type PCBs: up to L810 x W662 Note 2 Same type PCB: L810 x W280 to L50 x W500 Different type PCBs: up to L810 x W510 |

| Head / Applicable components | High-Speed Multi (HM) Head Note 3 0201mm to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) | X axis 2-beam Note 1: High-speed multi-purpose (HM: High-speed Multi) head x 2 81,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 2,110 x H1,445mm (Main unit only) |

| Weight | Approx. 2,500kg (Main unit only) |

- Note 1 : When using conveyor separation specifications of 787mm between 1 to 4 lanes

- Note 2 : When using conveyor separation specifications of 630mm between 1 to 4 lanes

- Note 3 : Please contact us for info regarding mounting 0201mm components.

- Specifications and appearance are subject to change without prior notice.