JUKI High-Speed Chip Shooter KE-3010A placement pick and palce machine

Features

Continued Evolution of the KE Series

Continued Evolution of the KE Series

| Chip | 23,500CPH chip (Laser centering / Optimum) 18,500CPH (Laser centering / IPC9850) |

|---|---|

| IC | 9,000CPH (Vision centering / MNVC option) |

- From 0402(01005) to 33.5mm square components

- One multi-nozzle laser head (6 nozzles)

- The use of electronic double tape feeders enables mounting of a maximum of 160 component types.

- High-speed, on-the-fly vision centering (When using both high-resolution camera and MNVC. (option))

- Longer sized PWB in X axis (option)

JUKI High-Speed Compact Modular Mounter RX-6R/RX-6B placement pick and palce machine

Features

| Placement speed | Chip : 52,000CPH*2 IC : 14,000CPH*3 |

|---|---|

| Component size | 0402mm(01005 inch) ~ 50mm×50mm*4 0402mm(01005 inch) ~ 100mm×100mm / 50×180mm*5 |

| Board size | Single lane conveyor: 50×50 ~ 610×590 / 905×590(2times clamping) Dual lane conveyor*6: 50×50 ~ 360×250 / 360×450(single lane conveyor specification mode) |

| Head unit | 6×6nozzle head 6×3nozzle head *6 |

- This is applicable to dual-lane production.*6

- Compact footprint : the width is just 1.25m

- Equipped with standard Placement Monitor check function.*1

- Replaceable head allow you to configure a production line best suited to the current repirments.*6

- High-speed component placement using high-speed non-stop vision recognition.*3

- Wide range of components and boards: tall components, large components and large boards.

- Brand new Matrix Tray Sever TR8S improves the component capability and productivity.

JUKI High-Speed Compact Modular Mounter RX-8 placement pick and palce machine

Features

- High-speed placements of up to 100,000 CPH.*¹

- Best-in-class placement rate per square meter(sq ft).*²

- Integrates seamlessly with the production enviroment

- Trace Monitor tracks quality throughout production process

- Low impact placement for flexible circuits

- The P20 high-precision planet head is ideal for high speed pocking and placing from a single reel.

- State-of-the-art centering and inspection vision system

- New high accuracy camera for inspection and centering

- *¹ Optimum conditions *² Market survey data

JUKI High-Speed Flexible Mounter KE-3020VA placement pick and palce machine

Features

Continued Evolution of the KE Series

Continued Evolution of the KE Series

| Chip | 20,900CPH chip (Laser centering / Optimum) 17,100CPH chip (Laser centering / IPC9850) |

|---|---|

| IC | 9,470CPH (Vision centering / MNVC) |

- From 0402(01005) to 74mm square components or 50×150mm

- KE-3020VA One multi-nozzle laser head (6 nozzles) plus one IC head with CDS sensor (1 nozzle)

- The use of electronic double tape feeders enables mounting of a maximum of 160 component types.

- MNVC is standard

- High-speed, on-the-fly vision centering (When using both high-resolution camera and MNVC)

- High speed feeding of tray components (Option)

- Longer sized PWB in X axis(option)

- PoP placement(option)

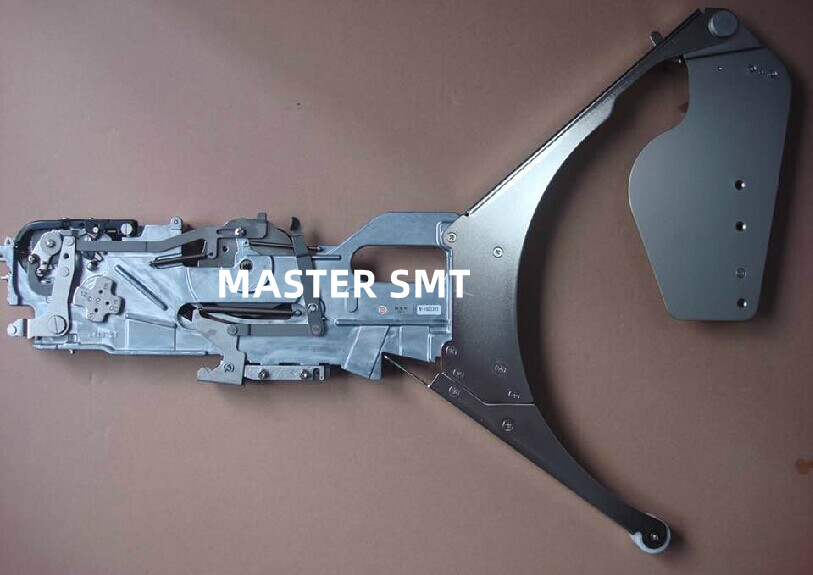

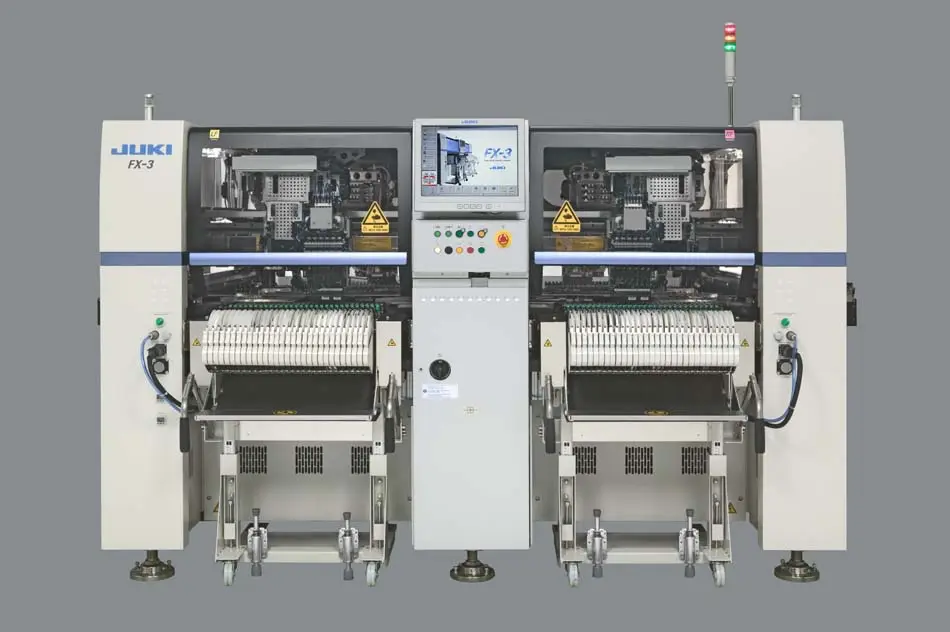

JUKI High-Speed Modular Mounter FX-3RA placement pick and palce machine

Features

| Chip | 90,000CPH (0.040Sec. / chip / Optimum) 66,000CPH (IPC9850) |

|---|

- 0402mm(01005 inch) ~ 33.5mm×33.5mm

- Laser recognition : ±0.05mm(±3σ)

- On-the-fly centering using integrated laser

- 2 stations, 4 gantries, 4 placement heads, 24 nozzles

- Linear servo motor XY drive with full closed-loop control

- Holds up to 240 components

- Electrical or mechanical feeder trolley