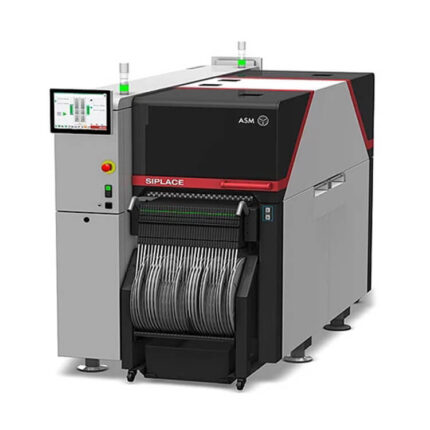

Technical Parameters:

C substrate size:

Monorail: L50mm*W50mm~L510mm*W590mm

Double track type: L50mm*W50mm~L510mm*W300mm

M substrate size:

Monorail: L50mm*W50mm~L510mm*W510mm

Double track type: L50mm*W50mm~L510mm*W260mm

Substrate replacement time

Single rail type: 4.0s (when no components are mounted on the reverse side of the substrate)

Dual-track type: 0s*When the cycle time is less than 4.0s, it cannot be 0S.

Power supply: three-phase AC200, 220, 380, 400, 420, 480V 2.5kVA

Air pressure source: Min.0.5MPa, 200L/min(A.N.R.)

Equipment size: W1300mm*D2798mm*H1444mm

Weight: 2690kg (Main body only: Varies depending on the configuration of options.)

Functional characteristics of Panasonic placement machine NPM-TT machine:

1. Basic specifications

1. The specification of the supply part can be selected (the tray feeder or the exchange trolley can be selected according to the variety and quantity of the component shape)

2. Mounting head (8-nozzle placement head, 3-nozzle placement head) (you can choose a versatile 8-nozzle placement head or a 3-nozzle placement head with special-shaped component capabilities)

3. Alternate mounting and independent mounting (the most appropriate mounting method can be selected according to the production substrate)

4. It can be directly connected to NPM-D (by directly connecting to NPM-D, it can form a production line that realizes high productivity per unit area and versatility at the same time)

5. It can correspond to the APC system (optional) (from microchips to packaged chip components, contributing to high-quality packaging)

2. Productivity

1. High productivity of completely independent mounting (realize independent mounting of tray components. Increase the speed of medium-sized and large-scale component mounting through the 3-nozzle placement head. Improve the overall output of the production line.)

2. Support pin automatic replacement function (option) (The position replacement operation of the support pin is automated, which contributes to the realization of non-stop machine switching, labor saving, and prevention of operating errors.)

3. Versatility

1. Correspondence to large components (can correspond to large components of 150*25mm, and QFP components of 80mm can also be identified through segmentation.)

2. Transfer unit (optional) (a camel-type transfer unit* is installed at the 13 stations fixed on the rear rack, which can be used to print and install PoP components (tapes, trays), etc.)

3. Free configuration of material racks (if they are in the same workbench, material racks can be freely configured. During production, components can be alternately arranged, and material racks for the next model can also be placed in empty material rack slots.)

Reviews

There are no reviews yet.