SMT concept

SMT: surface mount technology, abbreviation of surface mount technology.

The components are mounted on the designated PCB pads that have been coated with solder paste or glue, and then reflow or wave soldering is used to establish reliable mechanical and electrical connections between the components and the PCB pads.

Product production process selection

There are mainly three types of PCB board assembly methods:

Product production process selection-PCB board assembly methods mainly include the following three categories:

Assembly method Schematic diagram Circuit board Soldering method Features

full surface assembly

Single-sided table assembly

Single sided PCB

Single side reflow soldering

Simple process, suitable for small, thin and simple circuits

Double-sided surface assembly

Double sided PCB

Double-sided reflow soldering

High-density assembly, thinner

Surface mount + through hole reflow soldering

Single-sided PCB single-sided reflow soldering High-density assembly, plug-in wave soldering moved forward, through-hole reflow soldering reduces manpower and increases efficiency

Single side mixed installation

SMD and THC are both on side A

Double sided PCB

Reflow solder the A side first, then wave solder the B side.

Generally, it is pasted first and then inserted, which is a simple process.

THC is on side A and SMD is on side B

Single sided PCB

First, surface A is flow soldered, then surface B is wave soldered.

PCB has low cost and simple process. It is pasted first and then inserted. If the method is to insert first and then stick, the process will be complicated.

Double-sided mixed installation

THC has SMD on both sides A and AB

Double sided PCB

First, surface A is flow soldered, then surface B is wave soldered.

Suitable for high-density assembly

AB has SMD and THC on both sides

Double sided PCB

First, surface A is flow soldered, then surface B is wave soldered.

The process is complex and rarely used

Summary of SMT IPC standards

IPC stands for Institute of Printed Circuits

Summary of SMT IPC standards

1

IPC-7525

Stencil Design Guide

2

IPC-7527

Solder paste printing requirements

3

IPC/EIA J-STD-004

Flux requirements

4

IPC/EIA J-STD-005

Solder paste requirements

5

IPC-A-600

Acceptability of printed boards

6

IPC-A-610

Acceptability of electronic components

7

IPC-7711/21

Rework and repair of electronic components

8

J-STD-020

Humidity/Reflow Sensitivity Classification of Non-Hermetic Packaged Solid State Surface Mount Devices

9

J-STD-033

MSD humidity sensor management specifications

10

IPC-9853

Hot air reflow soldering system characterization and verification specifications

11

IPC-7530

Group soldering process temperature profile guide (reflow soldering and wave soldering)

12

IPC-7351

General requirements for surface mount device and land pattern standards

Abbreviations and definitions of professional English terms Term&Definition

Abbreviations Abbreviations Full English name Full spelling

English full name Full spelling

ACF

Anisotropic conductive film

AOI

Automated Optical Inspection

BGA

Ball Grid Array

BOM

Bill of Material

CMI

Capability Machine Index

CPI

Process Capability Index

pk

Process Capability Index

CSP

Chip Size Package

CTE

Coefficient of Thermal Expansion

EMS

Electronic Manufacturing Services

ENIG

Electroless Nickel and Immersion Gold

EPA

Electrostatic discharge Protected

ESD

Electrostatic Discharge

FG

Fine Grain

FOV

Field of View

FPC

Flexible Printed Circuit

GR&R

Gauge Repeatability & Reproducibility

HIC

Humidity Indicator Card

led

Light Emitting Diode

LGA

Land Grid Array

LSL

Lower Specification Limit

MBB

Moisture Barrier Bag

MSDS

Material Safety Data Sheet

OSP

Organic Solderability Preservatives

PCB

Printed Circuit Board

PCBA

Printed Circuit Board Assembly

PCN

Process Correction Notification

POP

Package on package

QFN

Quad flat no-lead package

QFP

Quad Flat Package

RCV

Receiver

RH

Relative Humidity

SAC

SnAgCu

SPK

Speaker

SMT

Surface Mount Technology

SOP

Small Outline Package

SOT

Small Outline Transistor

SPC

Statistical Process Control

SPI

Solder Printing Inspection

TDS

Technical Data Sheet

Tg

Glass-transition Temperature

USL

Upper Specification Limit

WLCSP

Wafer Level Chip Size Package

Wafer-level chip size packaging, that is, bare die chips; the manufacturer’s naming description generally starts with “WL”, such as WLNSP and WLPSP, which also belong to this type of device.

1 PCB QR code laser engraving machine

2 SMT printing stencil

3 SMT printing stencil cleaning machine

4 SMT printing stencil inspection machine

5 SMT printing stencil wiper paper / wiper cloth

6 PCB cleaning machine

7 SMT solder paste printing machine

8 SPI solder paste inspection machine

9 Leaded solder paste/lead-free solder paste/solid crystal solder paste/high, medium and low temperature solder paste

10 Leaded tin wire/Lead-free tin wire/Medium, medium and low temperature tin wire

11 BGA solder balls/lead-free BGA solder balls

12 BGA Ball Planting Machine (FlipChip, Concave BGA, PoP, SiP)

13 solder paste mixer

14 Dispensing equipment

15 SMT glue (red glue, solid crystal glue)

16 DIP glue (UV, three-proof, Underfill, Sidefill)

17 Carrier Tape. Cover Tape

18 SMD parts taping machine

19 SMD tape peel strength measuring machine

20 SMD strip vacuum forming machine

21 SMD parts counter

22 PCB sending/receiving machine and temporary storage machine

23 Pick & Place M/C Multifunctional SMT Machine

24 Pick & Place M/C High Speed SMT Machine

25 Pick & Place M/C Ultra-high-speed placement machine

26 AOI optical inspection machine

27 Reflow reflow oven

28 N2 Reflow nitrogen reflow oven

29 Lead-Free Reflow Nitrogen reflow oven for lead-free process

30 Vacuum Reflow vacuum reflow oven

31 Nitrogen generator

32 Furnace temperature tester

33 Flux/no-clean flux

34 Flux spray equipment

35 Substrate cleaning equipment (DI washing machine)

36 Cleaning chemicals

37 x-ray related

38 SMT rework equipment

39 BGA/CSP/FLIP CHIP rework equipment

40 2.5/3 dimensional inspection machine

41 Electron Microscope

42 Metallographic microscope

43 Intelligent ESD System Suppliers

44 Slicing and grinding machines

45 dryer/constant temperature and humidity oven/baking oven/warm impulse cycle/aging acceleration equipment

46 Wire bonding equipment (WireBonding, DieBonding)

47 SMT desktop equipment

48 FEEDER/NOZZLE

49 SMT used equipment suppliers

50 SMT Equipment Accessories Suppliers

52

MES system supplier

53

Second hand materials buying and selling supplier

54

Electronics factory scrap recycling supplier

55

PCBA maintenance parts outsourcing supplier

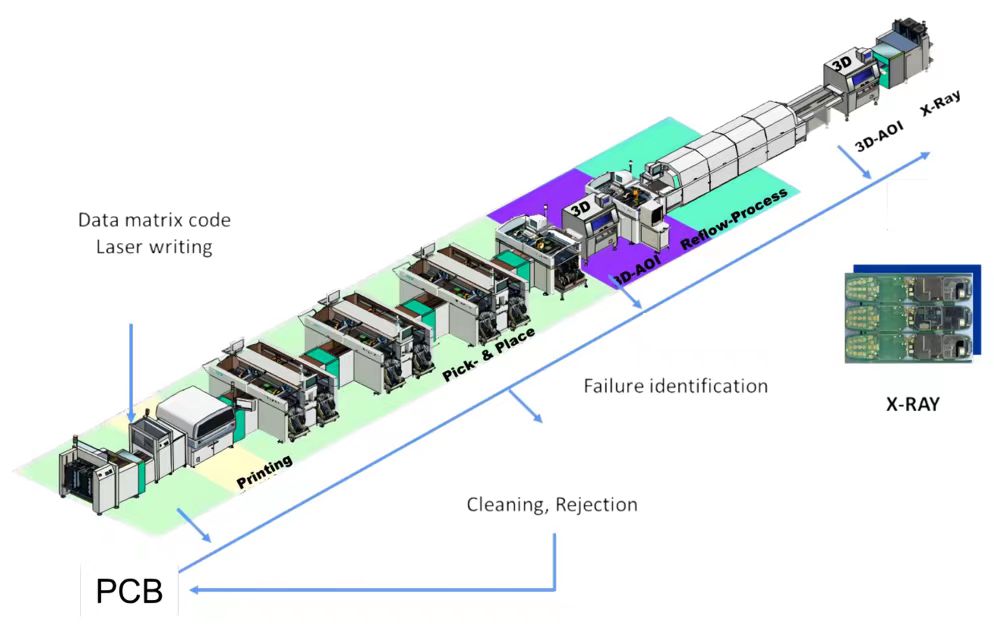

LOADER

AUTO LOADING MACHINE

Marking 1

laser marking machine

Print barcode on PCB

Marking 2

Inkjet marking machine

Spray on PCB Print barcodes to facilitate traceability of product dynamics and product life cycle tracking

clean

Dust removal and static air gun Perform dust removal, static electricity removal, and board dust and foreign matter removal on the PCB board to be printed.

print

Solder paste printing Print solder paste on PCB pads.

Dispensing glue

Red glue dispensing Dot the red glue on the solder resist between the pads of the PCB.

SPI

Solder paste printing quality inspection Check the length, width, shape and volume of the printed solder paste.

High speed machine

High speed placement machine High-speed placement of chip components

General purpose machine

Multifunctional medium speed placement IC, BGA, medium speed placement of larger components

Special placement

Special special-shaped structural component patch Special placement machines for special-shaped devices, including straight pin types for through-hole reflow Other large special-shaped parts

AOI

Optical automatic inspection of patch quality before furnace Conduct placement quality inspection on completed components

Hot air reflow soldering

Hot air reflow soldering Solder paste reflow soldering Vapor phase reflow soldering

IR infrared reflow oven

Solder paste reflow soldering

AOI

Post-furnace welding quality optical automatic inspection performs placement quality inspection on completed PCBA components

X-Ray

X-ray optical inspection machine performs X-ray perspective placement inspection on the internal and bottom quality of electronic components

Unloader

After AOI inspection, differentiate between NG/OK and frame, temporarily store, waiting for confirmation.

Barcode collection

Scanner gun After electronic scanning, enter and track the entire process quality status of semi-finished products.

Splitting machine 1

Online milling cutter depaneling Milling cutter method, cutting the entire Panel into small Set parts

Splitting machine 2

v-cut hob plate splitting machine Hob method, cutting the entire Panel into small Set parts

Splitting machine 3

Laser depaneling machine Laser method, cutting the entire Panel into small Set parts, suitable for PCBs with a thickness of 1.4mm and below

First article inspection machine

Automatic LCR measurement and confirmation of the first product produced

LCR

Bridge

LCR

Bridge

picture

Measuring instrument for measuring specific values of capacitors, resistors and inductors

Steel mesh cleaning machine

According to the frequency, remove the steel mesh and clean it thoroughly offline.

Solder paste mixer

Solder paste, glue and bubbles to make the proportions even

ICT testing machine

Flying probe testing machine

SMT basic knowledge

12

Dec