Industry 4.0 era.

Are you–

Are still acquiring SMT soldering standards through sample trial production?

Are you still manually determining the compliance of the furnace temperature profile?

Are you still organizing reports manually?

Are you still worried about device soldering compliance judgment?

PCB soldering process intelligent decision-making system to help you solve all the problems in one click!

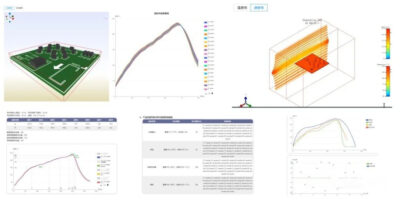

PCB soldering process intelligent decision-making system is a whole process simulation PCB SMT soldering heat process of intelligent simulation system. The system builds a digital PCBA model through virtualization, reflow oven model, associated solder paste, device, product process requirements, through thermal simulation software to achieve the solder joint temperature curve information acquisition, in order to establish a scientific reflow soldering process parameter setting method.

SMT engineers can use the automated thermal simulation analysis platform to achieve the furnace temperature curve loading, analysis model automatic processing, process welding simulation analysis, optimization, in order to enhance the efficiency of the furnace temperature debugging, and improve the SMT welding process research level.

PCB soldering process intelligent decision-making system full-process digital simulation of the SMT welding process, automatic simulation.

PCB welding process intelligent decision-making system core modules

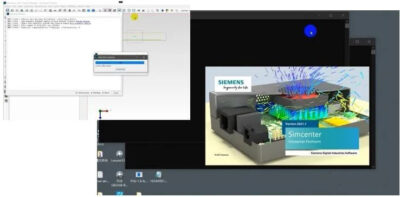

Thermal simulation tools

FLOTHERM based on CFD (Computational Fluid Dynamic, Computational Fluid Dynamics) principles, the system in the laminar flow, full-flow transition state of thermal conductivity, convection and radiation to solve the situation, to obtain a panoramic view of the system flow heat transfer.

The system uses it to create a virtual model of the SMT reflow soldering scene, perform thermal simulation and output soldering profile.

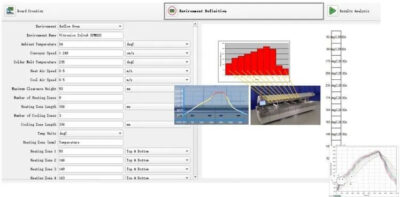

Reflow oven modeling

The system uses it to create a virtual model of the SMT reflow soldering scene, perform thermal simulation and output soldering curves.

Reflow oven modeling

According to the actual reflow oven temperature zone structure, transfer speed, use the heat transfer equation to solve the temperature distribution between the small temperature zones in the reflow oven, combined with the temperature of the small temperature zones, to establish the temperature curve in the reflow oven, and then based on the Transient to establish the corresponding simulation model to simulate the actual temperature environment.

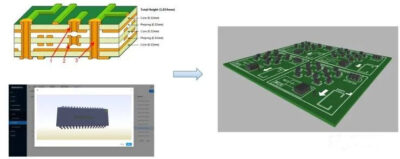

PCBA Modeling

This intelligent decision-making system analyzes the PCB design file by itself, obtains the PCB board information, device information, copper laying rate in the PCB design, and then combines the actual application BOM, device material information, and re-mounts the SMT type devices to form the PCBA digital model required for reflow soldering thermal simulation.

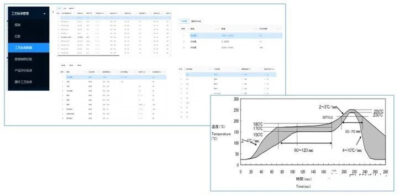

Process Standard Management

This intelligent decision-making system provides multiple dimensions of process standard management, not limited to solder paste process standards, but also includes device process standards, soldering defect experience, product evaluation and other process requirements. When outputting the report, the system can obtain these standards by itself, make comparisons, and output the results in the report.

Automated Simulation

After the user submits the simulation task, the system carries out the simulation run by itself and outputs the report automatically at the end of the run, so the user does not need to learn the operation of thermal simulation software.

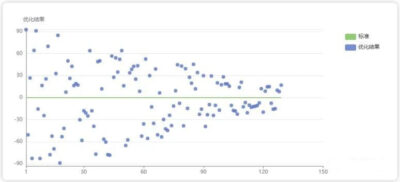

Optimization Algorithm

The system provides multi-objective optimization function based on the target parameters to realize automatic optimization of the furnace temperature curve and obtain the optimal furnace temperature setting parameters.

Multi-dimensional report

Users can choose the devices that need to output results, and each device provides simulation results in multiple positions, in addition to the process standards, and quickly display the judgment results.

Task Scheduling, System Management

The system provides simulation task management function, users can according to the actual situation, simulation task queuing management. In addition, it provides the function of sending results by e-mail, so that users can obtain information in time without having to check the system frequently.