JUKI2050 placement machine Mounter placement pick and palce machine

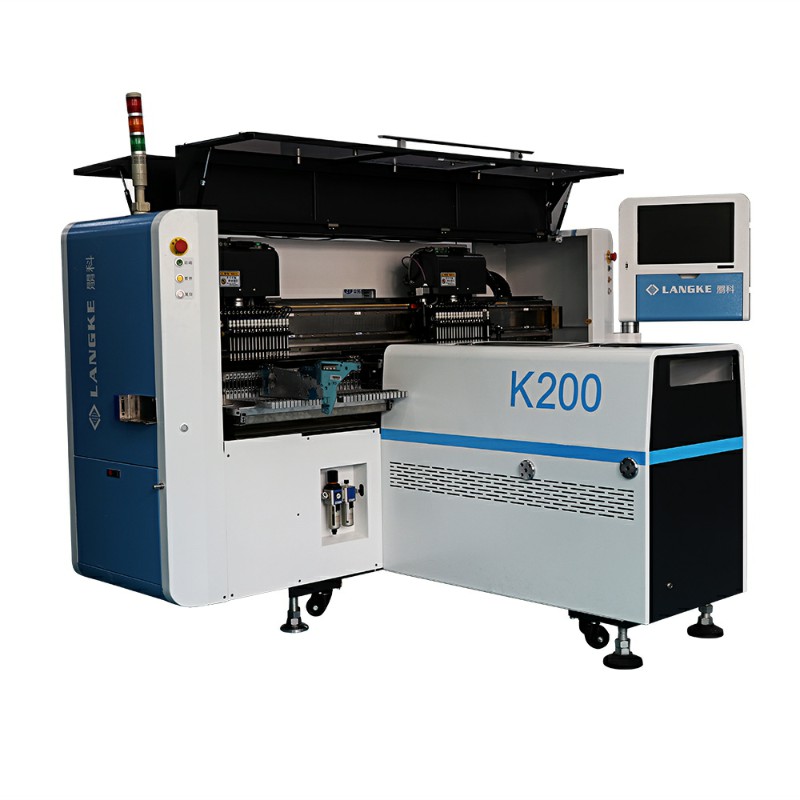

Langke K200 led chip placement Pick&Place machine

Langke L500 supper high speed placement pick and place machine for RGB wireless strip light

Langke LK-T8 Mulit-function pick and place machine

Langke S500 led chip placement machine Pick&Place machine

MIRAE MX200L PICK AND PLACE MACHINE MOUNTER

Panasonic CM202 placement machine Mounter

Main parameters of CM202 placement machine:

2004 equipment

PCB size: 460mm×360mm

Component range that can be attached: 0201 to 24mmQFPS

Material station: 104

Theoretical placement speed: 0.088s/chip 40909 pieces/hour

Mounting accuracy: ±0.05mm

Dimensions and Weight: 2,350(L) X 1,950(D) X 1,430(H)mm&2,800kg

Power supply and air source: 3P/200V±10V/3KVa

Panasonic Mounter CM402-L Modular Super High Speed placement machine

Model name: CM402-L

Substrate size: L50mm×W50mm~L510mm×W460mm

Substrate replacement time: 0.9s (when the substrate length is below 240mm and under the best conditions)

Power supply*1: three-phase AC200V, 3.5kVA

Air pressure source*2: 0.49MPa, 150L/min (A.N.R.)

Equipment size: W2350mm×D2690mm×H1430mm*3

Weight*4: 3000kg

High-speed placement head

Mounting fastest speed: 0.06s/chip (Type A)

Mounting accuracy: ±50μm/chip (Cpk≧1)

Component size: 0603 chip~L24mm×W24mm

Multifunctional placement head

Mounting fastest speed: 0.21s/QFP (Type B)

Mounting accuracy: ±35μm/QFP (Cpk≧1)

Component size: 0603 chip~L100mm×W90mm

Panasonic Mounter CM602-L high-speed placement machine

Control mode: microcomputer mode

External memory: Manage data at PT∗4. Each set of data requires about 1MB. (1 type is required for each 1 type 3.5 2HD floppy disk)

Program data: Points Max. 10000 points

CM602 power supply

Power supply for normal use: 3-phase AC 200 V/ 220 V ±10 V, 3-phase AC 380 V/ 400 V/ 420 V/ 480 V ±20 V Frequency: 50/60 Hz

Power supply for HUB ∗ 3: Single-phase AC 100 V ~ AC 240 V Frequency: 50/60 Hz

Rated capacity: main machine 4.0 kVA / HUB power supply ∗ 3: 140 VA

Supply air pressure: 0.49 MPa ~ 0.78 MPa (operating air pressure is 0.49 MPa ~ 0.54 MPa)

Supply air volume: 170 L/min (A.N.R.)

Dimensions: 2350 mm (W) × 2690 mm (D) × 1430 mm (H) (excluding 3-section signal tower and color touch panel)

quality:

Mass of the main engine: 3400 kg (140 kg for the standard configuration without the overall exchange trolley)

Overall exchange trolley mass: 140 kg (per 1)

Direct tray feeder mass: 195 kg (per 1 unit)

Standard composition mass: 3960 kg (1 main engine, 4 overall exchange trolleys)

Environmental conditions: Temperature: 10°C ~ 35°C Humidity: 25% RH ~ 75% RH (but water vapor does not condense)

Transport and storage conditions: Temperature: −20°C ~ 60°C Humidity: Below 75 % RH (but water vapor does not condense)

Altitude: from 0 m above sea level to below 1000 m

Noise: < 70dB (A)

Panasonic Mounter NPM-TT2 multifunctional production system placement machine

The Panasonic Mounter NPM-TT2 is a line configuration capable of achieving both high productivity per unit area and versatility *When directly connecting the NPM-W2, an M-size double-track conveyor belt (optional) is required. The placement head (8-nozzle placement head, 3-nozzle placement head - you can choose the general-purpose 8-nozzle placement head or the 3-nozzle placement head with special-shaped component capability) The specification of the supply part can be selected .change. By reorganizing the tray feeder/exchange trolley, the line configuration can be adapted to the component supply form. Using a multi-functional recognition camera, the recognition and inspection of the height direction of the components can be realized at a high speed, and it can carry out stable and high-speed mounting of special-shaped components) Alternate mounting and independent mounting correspondence

——(can choose the best mounting method corresponding to the production substrate)